Pyroplas® converts mixed plastic waste into valuable energy sources like gas and liquid fuels. Utilizing a plasma pyrolysis process, Pyroplas breaks down plastic at high temperatures without oxygen, preventing harmful emissions like CO2, dioxins, and furans. This eco-friendly system transforms waste into clean energy while significantly reducing the need for incineration and landfill.

Pyroplas® is an innovative plasma-based pyrolysis technology designed to revolutionize plastic waste management. By utilizing high-temperature decomposition in a low-oxygen environment, Pyroplas® transforms mixed plastic waste into valuable products like synthetic fuels and carbon black. This eco-friendly solution eliminates harmful emissions, reduces landfill dependency, and supports energy sustainability. Scalable and mobile, Pyroplas® offers industries and municipalities an efficient way to convert waste into resources while significantly lowering their environmental footprint.

Pyroplas® operates without oxygen, meaning no CO2, dioxins, or furans are produced during the process, making it a clean alternative to traditional incineration.

The system consumes only 10-15% of the energy it generates, making it highly efficient. The rest of the energy can be used on-site or sold back to the grid.

Pyroplas® units are containerized, making them easy to transport and deploy in various locations, whether on industrial sites or remote areas.

Industrial waste management: Large manufacturers, such as food and beverage companies, can reduce their waste footprint and generate their own energy.

Municipal waste solutions: Cities and municipalities can adopt Pyroplas® to manage plastic waste more sustainably.

Remote locations: Pyroplas® is ideal for off-grid applications, providing energy solutions where traditional power sources are not available.

Viridhys is preparing to roll out Pyroplas® units across Europe, North America, and beyond. With growing demand for cleaner waste management solutions, the expansion of Pyroplas will help industries and governments meet their sustainability goals while reducing reliance on fossil fuels.

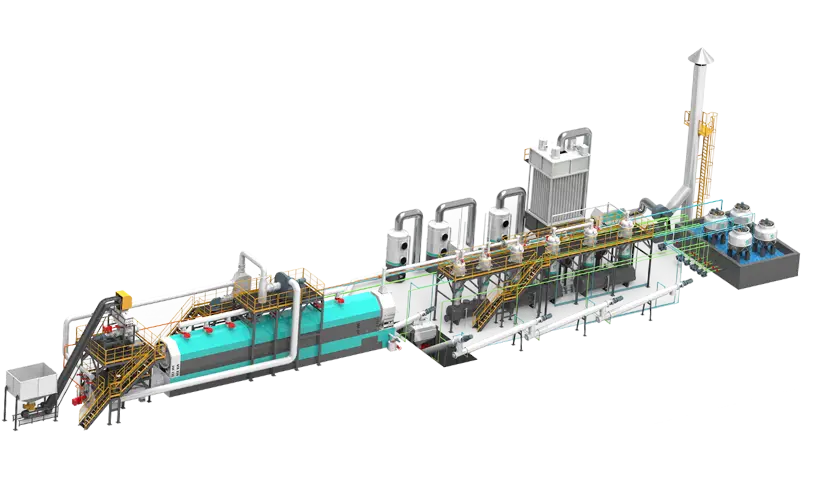

Pyroplas® is a cutting-edge plasma pyrolysis system designed to process and transform mixed plastic waste into valuable products like synthetic fuels and carbon black. It operates in a low-oxygen environment to ensure clean, efficient energy recovery without harmful emissions.

The Pyroplas® system heats plastic waste to high temperatures in the absence of oxygen, breaking it down into its chemical components. The process yields fuels such as diesel and gas, while capturing and repurposing any residual gases for energy self-sufficiency.

Pyroplas® minimizes waste by transforming it into usable products, significantly reducing landfill dependency. It operates with low CO2 emissions, avoids producing harmful byproducts like dioxins or furanes, and reduces the need for fossil fuels through its energy recovery process.

Industries generating plastic waste, municipalities, and recycling facilities can benefit from Pyroplas®. It offers a sustainable and economically viable solution for managing waste while producing energy and other valuable materials.

Yes, Pyroplas® systems are designed to be flexible and scalable. They can be installed on-site as modular, containerized units, making them accessible for both small-scale operations and larger industrial applications.

Viridhys develops sustainable technologies for waste reduction and energy efficiency. Innovations like Pyroplas for clean fuel from waste, PlasmaSeed for eco-friendly seed treatment, and MCS for green cooling solutions help advance a cleaner, circular economy and promote sustainable agriculture worldwide.

Made with ♥ by successfactor Sàrl